ENDRESS conveyor technology: reliable, robust, powerful

To ensure that your wood combustion system runs without interruption, ENDRESS offers reliable and durable conveyor technology for the automatic discharge and transport as well as the feeding of the different fuels.

We advise you on the selection of storage containers, silo discharge, conveyor systems and screw conveyors. High-quality materials and components ensure trouble-free operation.

Common product types

Articulated arm milling machine type GS 25-60

for wood industry waste and chip briquettes Diameter 2.5 m - 6.0 m

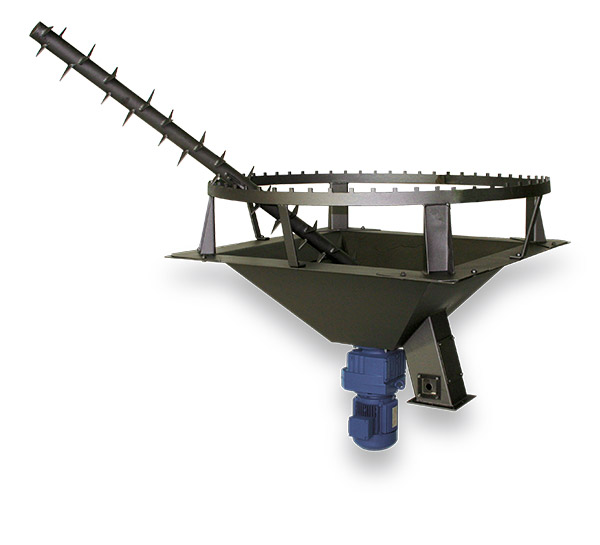

Leaf spring agitator type FP 25-60

for pellets and wood chips

Inclined screw type SA 35-75

for wood chips with dust content and wood chips diameter up to 7.5 m

Chip discharge type SL 8-12

for wood industry waste and planing waste Silo diameter up to 12 m

Truck extraction screw conveyor

Excess fuel capacities can be removed quickly and easily using an extraction screw.

Hydraulic push floor discharge type H

for wood industry waste, briquettes and wood chips

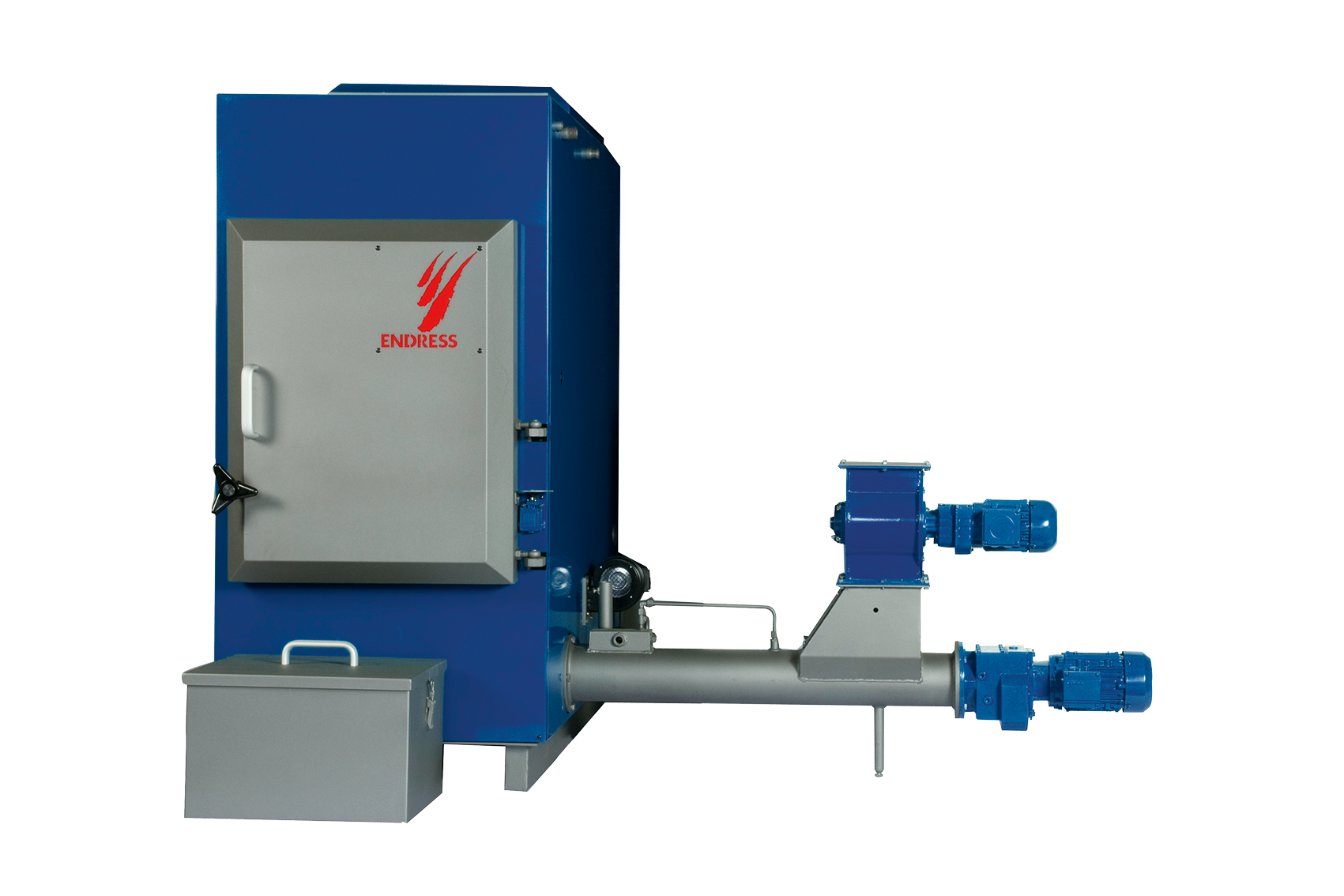

Supply metering / distribution container type VB

for wood chips and chip briquettes

Swap container type WEC

for wood industry waste, wood chips and chip briquettes

Screw conveyors

Customised conveying technology, the right screw conveyor for every fuel.

Individual solution by virtue of intensive consultation

ENDRESS adapts the conveyor technology perfectly to your wood combustion system. We combine every offer with a specific installation proposal, which is individually oriented to your annual heat requirements, type and quantity of waste wood produced, as well as the space available on your premises.