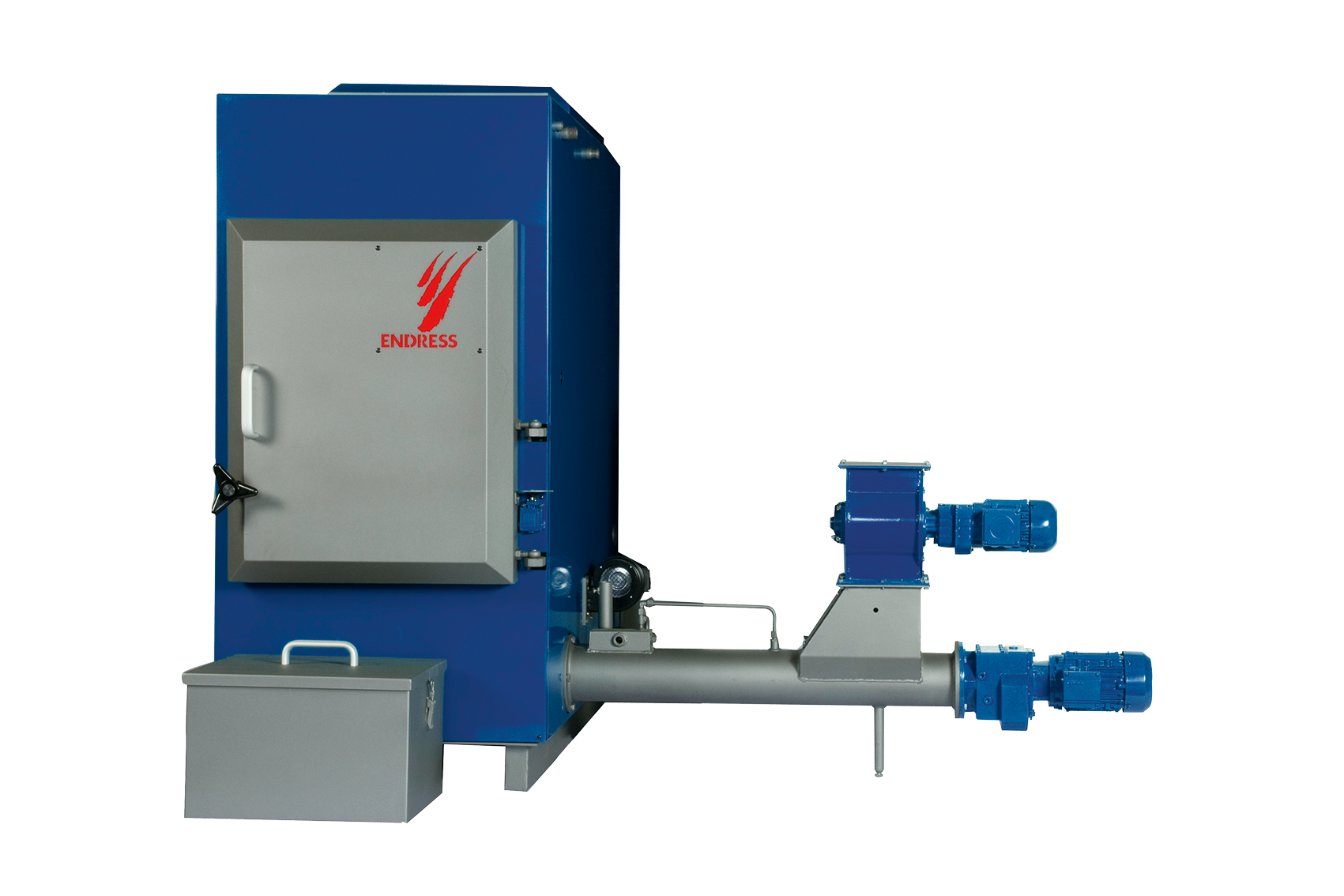

USF-W

Underfeed combustion 250 - 1000 kW

The modern ENDRESS USF-W wood combustion system is designed for an output of 250 to 1000 kW and impresses with its high efficiency.

Suitable for dry fuels such as wood chips, wood briquettes, pellets, sawdust, sanding dust and shavings - especially also for fuels of classes 6 and 7.

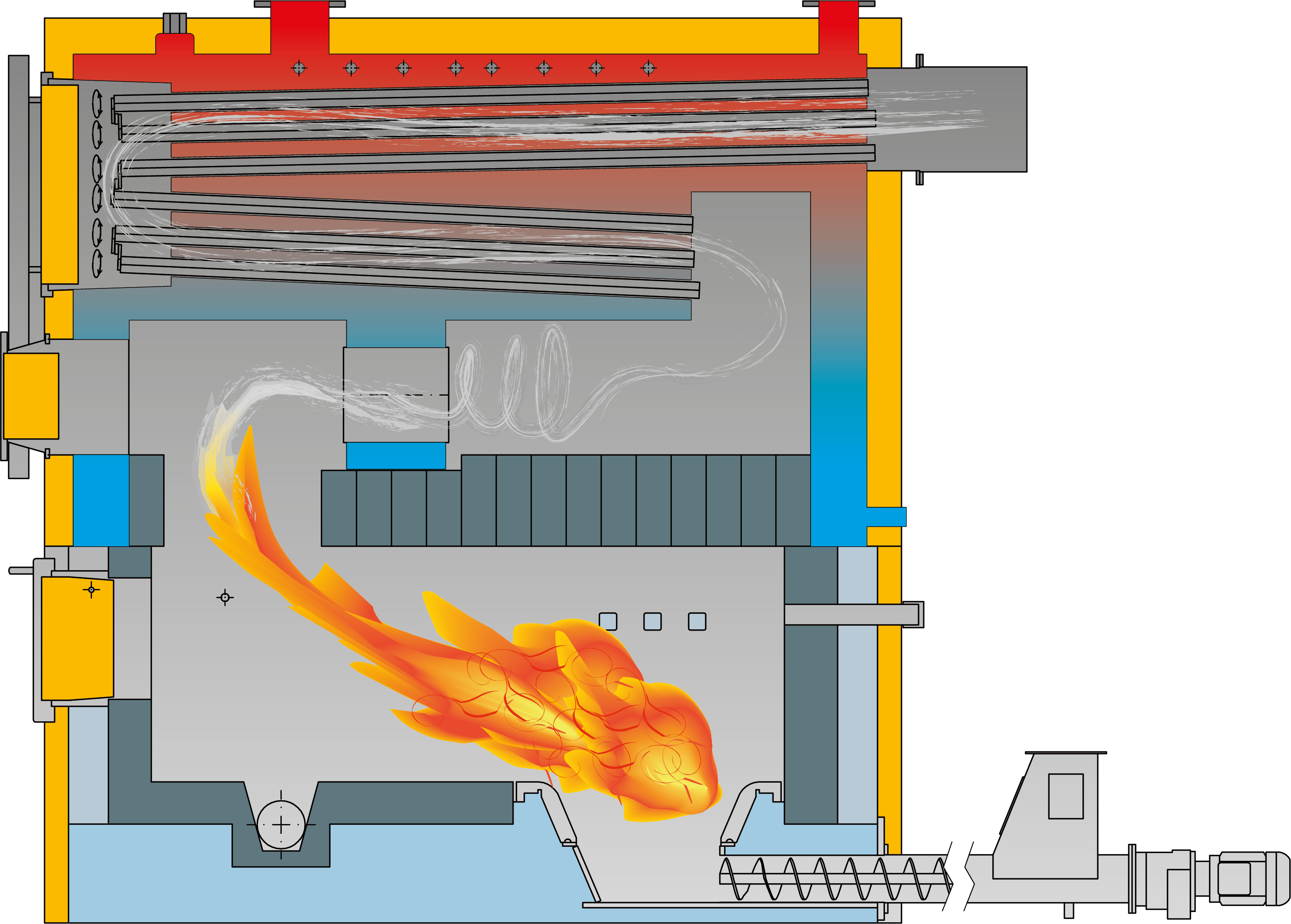

Ingenious design

Horizontal tube heat exchanger

High thermal performance: Large-volume, high-performance heat exchanger in 3-pass design

Automatic cleaning

High comfort: The permanent removal of ash deposits from the heat exchanger and combustion trough ensures a consistently high boiler efficiency, prolongs the cleaning intervals and saves time as well as cleaning material.

4-sided ventilated combustion chamber

High efficiency: Clean combustion by virtue of 2-sided, controlled ventilation of the cantilever combustion chamber made of high-temperature ceramic cement. The 15 mm thick steel firebox retort has an automatic ash discharge and a standard ash container

High temperature resistant grate bars

Long service life: Grate bars of the underfeed retort are made of high-temperature resistant cast stainless steel; with 27 % chrome content.

Automatic ignition

Comfortable heating: A sophisticated ignition programme, in conjunction with the temperature-controlled ignition fan, ensures simple, material-saving heating.

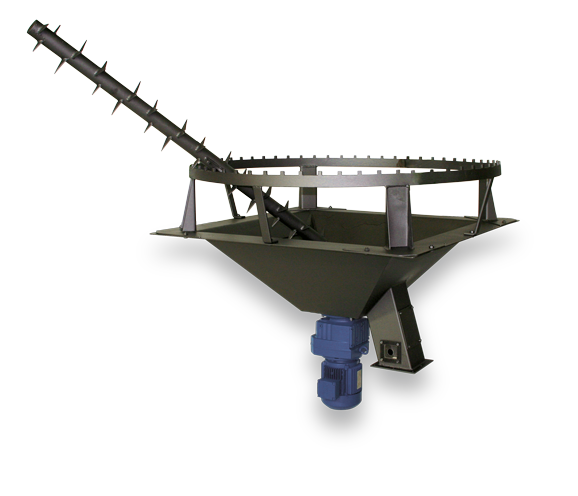

High quality drives

Made in Germany: The stoker screw and ash discharge are driven by high-quality geared motors.