Heat generation from wood is important for climate protection

Timber construction is active climate protection, because wood stores climate-impactingCO2 over its entire useful life and building with wood generates significantly less grey energy than building with conventional building materials. If the raw material also comes from regional, sustainably managed forests, this further reduces theCO2 footprint. A third pillar for sustainable management with wood is offered to companies active in timber construction and wood glue production through the energetic utilisation of the wood residues produced in production as well as chips, sawdust and sanding dust. Instead of expensive disposal, all or part of the heat for the workshop, buildings and drying plants is provided for free - and only the same amount ofCO2 is released that the wood had previously taken from the environment and stored.

Suitable for all dry wood fuels

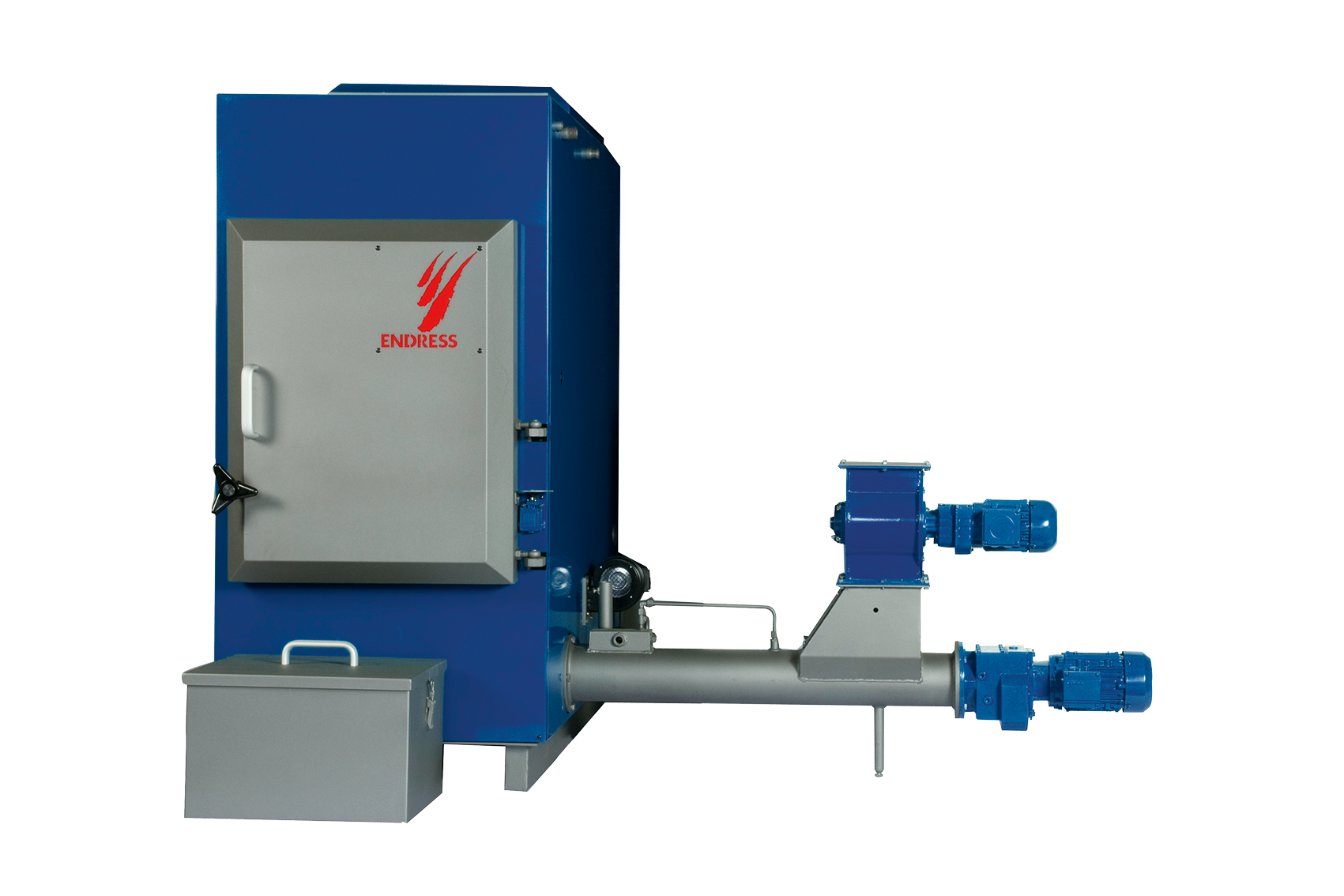

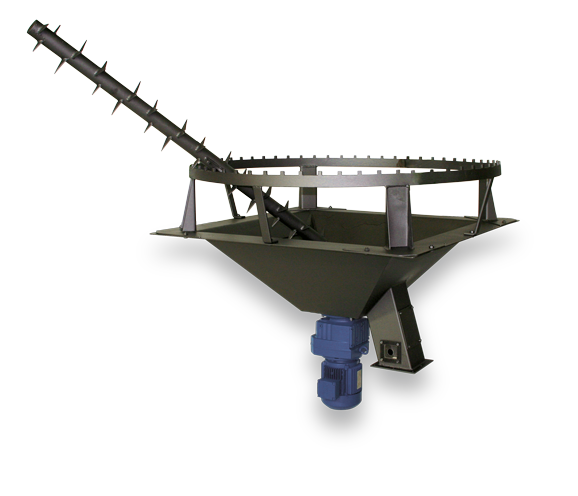

Not all fuels are the same, even if they are wood. Emissions and combustion behaviour change depending on whether chips, dust or residual wood are burnt. Using an ENDRESS wood combustion system, all permissible, dry wood fuels such as wood chips, wood briquettes, pellets, sawdust, sanding dust and shavings - in particular also fuels of classes 4 and 5 such as glued wood - can be utilised.

Depending on the annual heat requirement for heating production halls and buildings, generating hot water and providing process heat, the boiler, buffer storage, fuel preparation and conveying technology are always individually dimensioned - and with an eye to the future.

Do you have any questions or would you like to receive individual advice from our professionals?

ENDRESS adapts your new combustion plant individually to your annual heat requirements, the type and quantity of waste wood produced and the space available on your site. Each offer is combined with a specific installation proposal.