Scraps of material from wood become sustainable heat

Burning wood residues from production and using them to supply heat to factory rooms, administration buildings and paint shops has a long tradition among carpenters, furniture makers and window makers – it does after all save on expensive disposal costs. Since the beginning of the millennium, the recurring discussion about particulate matter emissions that are hazardous to health and the resulting stricter limits have caused uncertainty in the industry. ENDRESS took up the challenge at an early stage and developed its own particulate matter filter. This means that the emissions of an ENDRESS wood combustion system remain under the current limit set by the 1. BImschV of 0.02 g/m³.

Perfect in meeting fluctuating energy requirements by virtue of its rapid controllability

Both under partial load and under full load, ENDRESS wood combustion systems reliably achieve efficiency in exc 90 %. Where energy efficiency is concerned, this form of heat generation is virtually unbeatable. For joineries and cabinet makers, however, other aspects play a role in the investment decision. Time is money and you want to spend it on your craft if possible, not on cleaning the boiler or feeding the fuel.

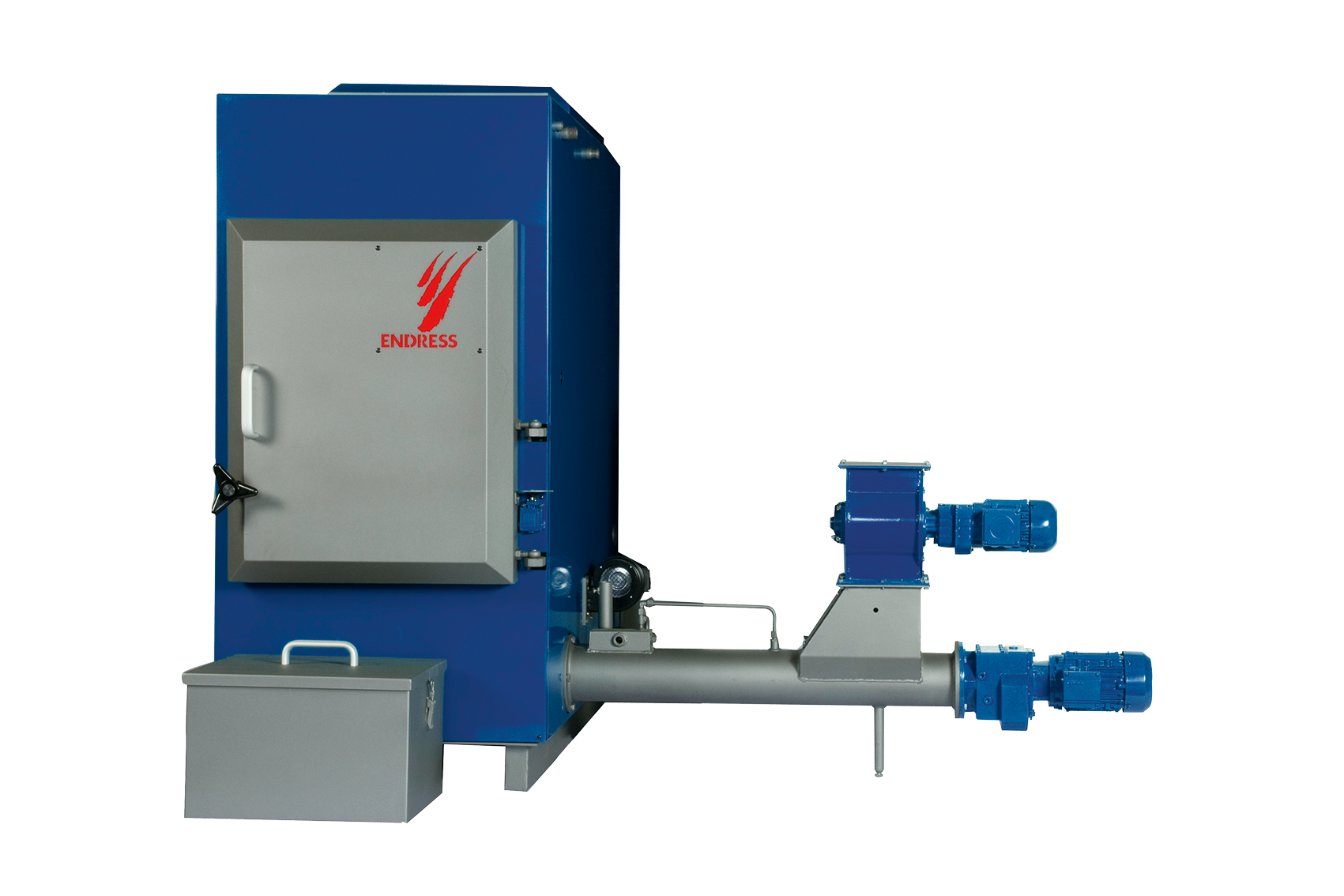

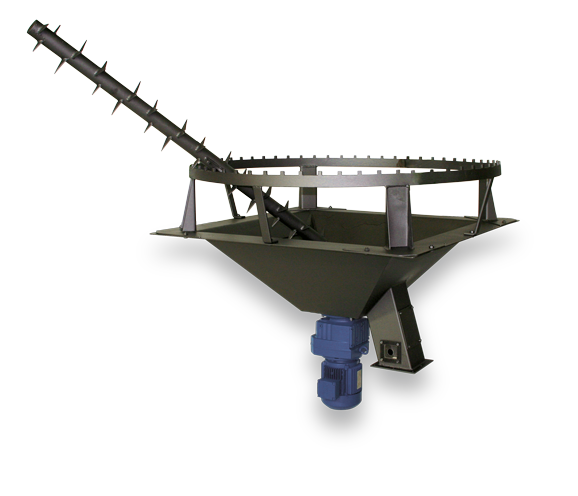

ENDRESS underfeed furnaces offer automatic ignition, automatic heat exchanger cleaning and automatic ash removal. Furthermore, it is important to plan the system comprehensively, while always taking into account the local space conditions. ENDRESS advises joineries on the selection of plant components for shredding, storage, discharge and feeding of the fuels.

Do you have any questions or would you like to receive individual advice from our professionals?

ENDRESS adapts your new combustion plant individually to your annual heat requirements, the type and quantity of waste wood produced and the space available on your site. Each offer is combined with a specific installation proposal.