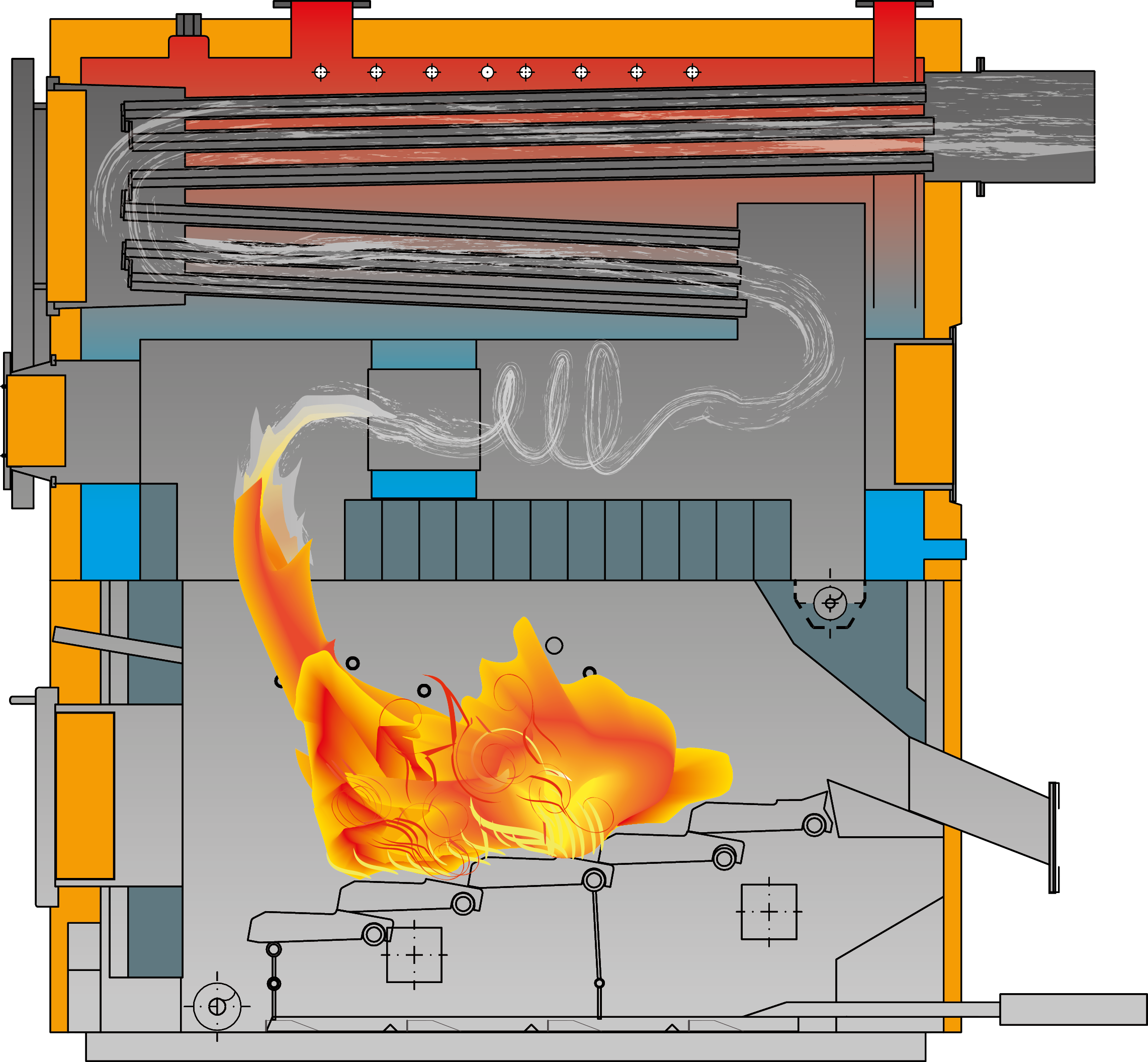

The modern ENDRESS VR-W wood combustion system offers maximum efficiency with low material input. Designed for an output of 250 to 900 kW.

Wood combustion system for fuels with a water content of up to 50 %

Powerful infeed grate combustion250-900 kW

The high-quality ENDRESS USF-W wood combustion systems set standards: compact, economical and user-friendly in every respect.

Ingenious design

Automatic cleaning of heat exchanger and boiler

High comfort: The permanent, fully automatic removal of ash deposits from the heat exchanger and boiler, as well as the generously dimensioned water content, ensure consistently high levels of boiler efficiency, prolong cleaning intervals and save time.

Adjustable 2-zone airflow

In the self-supporting combustion chamber made of high-temperature ceramic cement, the large 2-stage grate, the separately controllable 2-zone airflow and the undergrate ash removal with push-through bottom ensure clean combustion.

High temperature resistant grate bars

Self-cleaning and cooling guarantee the high-temperature resistant stainless steel rods a long service life.

Automatic ignition for fuels up to W35

Comfortable heating: A sophisticated ignition programme, in conjunction with the temperature-controlled ignition fan, ensures simple, material-saving heating.

High-quality drive technology

Made in Germany: Fuel discharge and ash discharge are driven by high-quality geared motors. A central hydraulic unit is responsible for the movement sequences of the material feed pistons, grate, wedge feed floor and heat exchanger cleaning.