The Rankers organic market garden in Straelen, North Rhine-Westphalia, sells its products under the LA'BIO! brand, sending a clear message to consumers throughout Germany and in neighbouring Holland: All LA'BIO! products are grown purely organically and without the addition of artificial fertilisers or sprays and thus stand for unadulterated organic enjoyment. But for the Rankers family, sustainability involves more than just organic farming. "We want to go completely green throughout the entire process chain," was the brief given to ENDRESS. And we delivered: We designed and supplied a wood combustion system that generates the process heat for the greenhouse with the certified biofuel Pellet DIN+ in an energy-efficient and climate-friendly way.

Combustion technology

Underfeed combustion USF-W 1000 | 900-1100 kW

Filter technology

Tubular fabric filter RGF

In operation

since 2020

Fuel

Pellets

The challenge:Energy-efficient, sustainable process heat

TheCO2 tax oncoal was only the final impetus to replace the old coal-fired furnace, which had been used to generate process heat for the Rankers greenhouses until then. Since the Rankers family has proclaimed the goal of "100 % green" for their organic horticulture business, naturally only heat generation from regenerative sources came into question. A not inconsiderable economic advantage: Up to 55 % of the eligible investment costs for systems that generate process heat with biomass are subsidised by the state (as of July 2021).

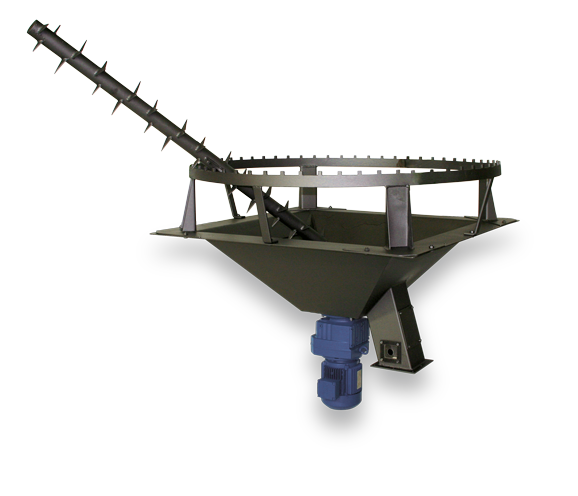

After weighing up all the alternatives, the decision was made in favour of industrial pellets and the search was on for a reliable wood combustion system that would also react quickly and flexibly to the highly fluctuating temperatures in the greenhouse. Thanks also to the state-of-the-art control technology, the choice was made in favour of a USF-W 1000 Underfeed combustion system from ENDRESS.

"Preserving natural resources is important to us throughout the production process."

Swen and Danny Rankers Management LA'BIO!

The solution:Perfectly coordinated plant technology

Wood pellets usually come from sustainable regional production. The customer's wish to use industrial pellets of always the same quality as fuel facilitated the customised design of the control system and particulate matter filter for our experts. Our team in Burgbernheim was responsible for the entire planning and order processing, including heating construction and electrical installation.

The pellet combustion system was accommodated within the existing installation room, and the pellet silo with a diameter of 5 metres, in which around 80 m3 of pellets can be stored, was installed outside. By virtue of our in-house developed ENDRESS particulate matter filter RGF 1000, emissions remain below the limit value of 0.02 g/m³ (according to 1st BImschV). The already excellent efficiency is increased even further by an additional flue gas heat exchanger.

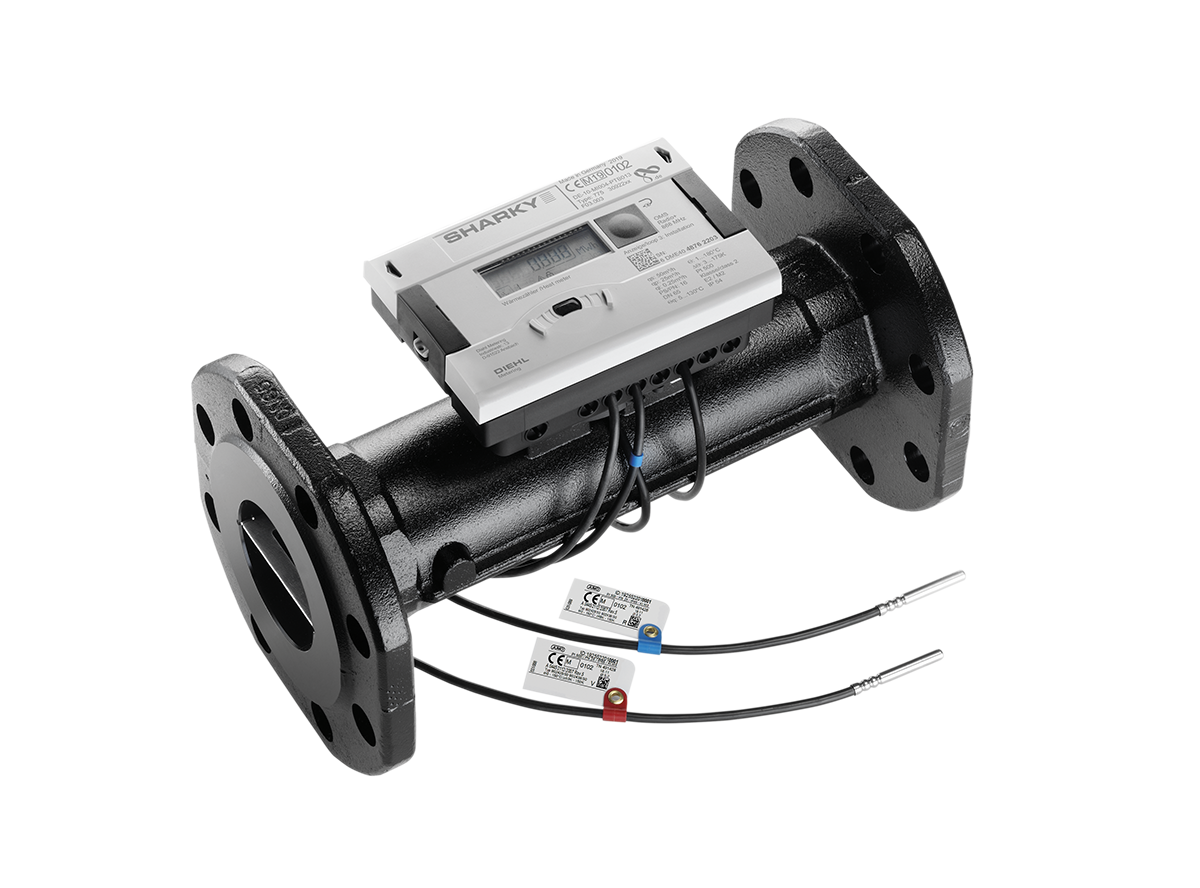

The heating is controlled via an external climate computer, which is responsible for the automation of all technical systems in the greenhouse. Rankers added two options when the order was placed: An integrated energy data collection system records all consumption and enables easy evaluation and visualisation of trends. In the event of a malfunction, the employees can access the system control remotely using the online service I-SPY and can react immediately.

"Our system technology is extremely robust and low-wear, which is why we provide a 10-year guarantee on our boilers," explains Managing Director Klaus Endress. For greenhouse operations such as Rankers that want to convert to green in a holistic way, a modern ENDRESS pellet furnace offers a whole range of sustainable advantages: natural wood pellets are practically climate-neutral, the particulate matter filter guarantees a separation efficiency of more than 99 % and operation is exceptionally maintenance-friendly.

Do you have any questions or would you like individual advice?

ENDRESS adapts your new combustion plant individually to your annual heat requirements, type as well as the space conditions on your site. Each offer is combined with a specific installation proposal.