Raised floors are commonplace in data centres, technical rooms, laboratories, production halls and clean rooms. Floor panels made of flame-retardant or non-combustible materials lie on supports made of steel or aluminium. The electrical and data lines for the supply of computers and equipment are concealed in the cavity below. Since 1975, today's Weiss Doppelbodensysteme GmbH in Satteldorf has specialised in the production of such high-quality system floors. In 2020, the company settled in Satteldorf, Baden-Württemberg. The 6,000m2 production hall is conveniently located for the A6 motorway and also in the immediate vicinity of Knauf Integral, the main supplier of plasterboard blanks. Gypsum (chemical name calcium sulphate) is the most important material for floor panels, along with highly compressed chipboard, because it is non-combustible and has excellent soundproofing properties. Despite the optimisation of logistics through the short distances, the gypsum boards, like all raw boards, still have to be protected during transport. Chipboard above and below the delivered stacks ensures that the precisely finished edges remain intact and can be further processed.

Combustion technology

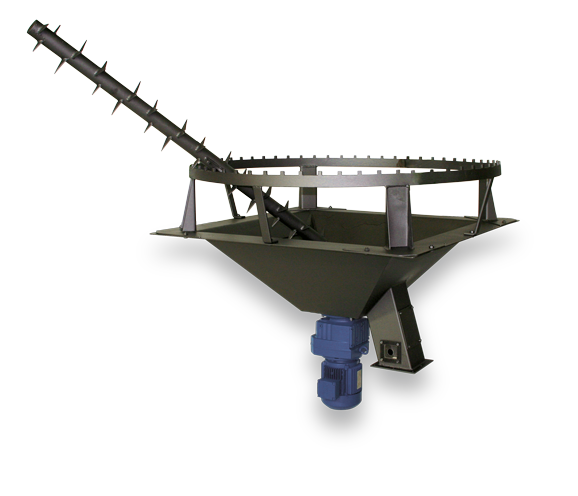

Underfeed combustion USF-W 800 | 600-800 kW

Conveyor technology

Articulated arm milling machine type GS

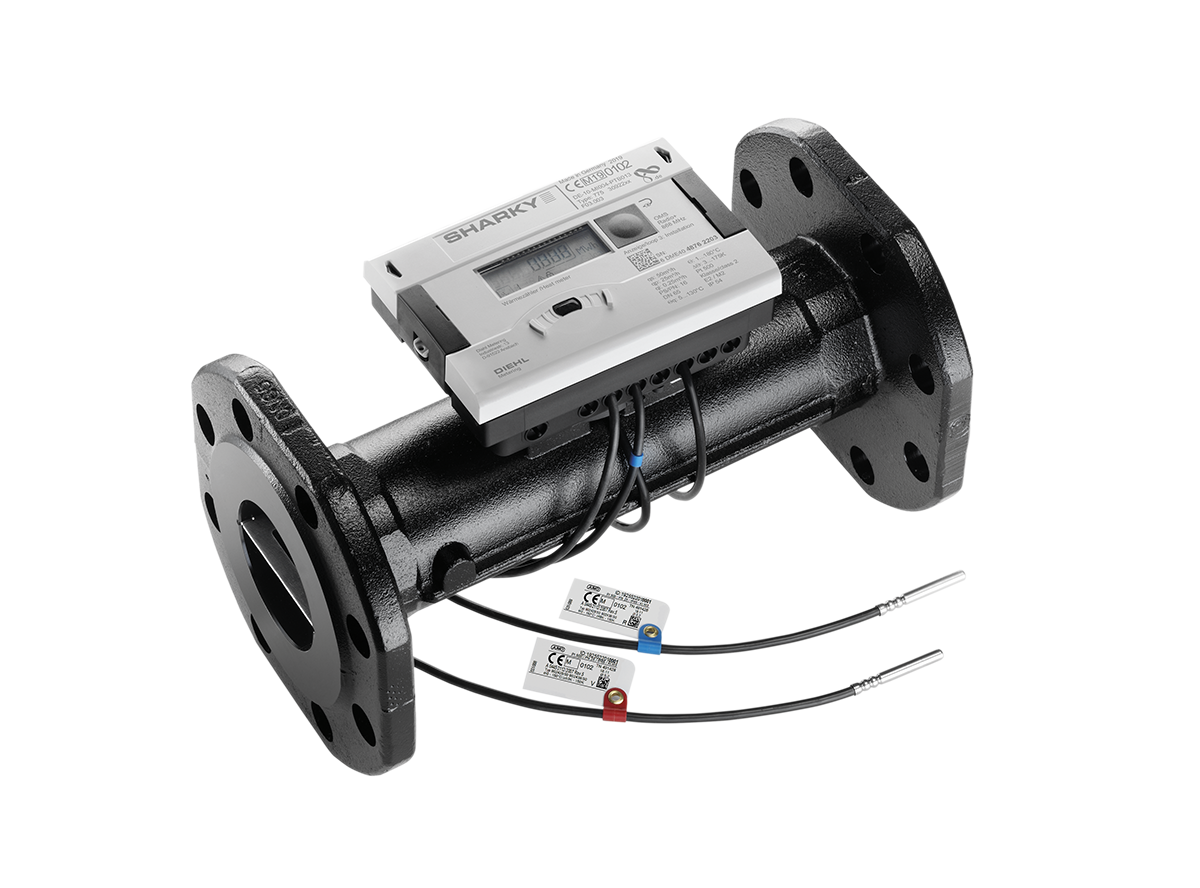

Heating circuits

Heating circuit control

Buffer tank

two 12,000 L PUMPERS

In operation

since 2020

Fuel

Packing wood

The challenge:Green thermal energy

With disposable pallets and chipboard, Weiss Doppelbodensysteme therefore collects a lot of waste wood every day. In order to avoid having to dispose of this waste at great expense, the team led by Managing Director Viktor Grünwald decided to install a wood combustion system at the new location and to use the packaging wood as fuel for energy generation. In addition to the holistic plant technology from the shredding to the wood combustion, regionality was also an important selection criterion. ENDRESS is less than 50 kilometres away from Satteldorf. The best prerequisite for good cooperation.

"Industrial space heating with wood heat as a regenerative energy source conserves resources and creates a perfect indoor climate in production."

Klaus Endress, Managing Director ENDRESS Holzfeuerungen

The solution:Overall concept must fit

ENDRESS fitted perfectly into the company's philosophy of becoming green and sustainable and was able to realise the project quickly. Together with a USF-W 800 underfeed combustion system, a chipper with magnetic separator and an automatic feed to the fuel store were commissioned in record time. Two 12 m³ buffer storage tanks absorb peak loads. The control cabinet with control and an ENDRESS particulate matter filter round off the complete package.

Weiss Doppelbodensysteme chose an underfloor heating system with concrete core activation to heat the production hall. The flow temperatures can be selected very low, the large pipe bodies store a lot of heat, but the biggest advantage is that no dust is whirled up, because the temperature of the rooms is largely controlled by radiant heat and not by heating the air as with conventional radiators. An important criterion in many industrial operations.

Managing director Grünwald and his team are completely satisfied. The ENDRESS wood combustion system makes a major contribution to reducing CO2 emissions during operation. Although it is extremely low-wear by virtue of its solid construction, a maintenance contract also ensures that the system is always 100 % reliable. The online service I-SPY enables direct access to the system control and the Weiss team can react immediately in the event of a malfunction.

Do you have any questions or would you like to receive individual advice from our professionals?

ENDRESS adapts your new combustion plant individually to your annual heat requirements, the type and quantity of waste wood produced and the space available on your site. Each offer is combined with a specific installation proposal.