Moser GmbH from Haslach has made a name for itself as a specialist for components made of solid surface material.

Almost exactly three decades ago, Thomas Moser took over his parents' carpentry business in Haslach, Baden-Württemberg. Annual turnover at the time: DM 600000. What he has made out of it since then is impressive: a company with around 100 employees that is equally at home in window construction, shopfitting and interior design as well as solid surface processing.

The window construction division sells timber and timber-aluminium windows with its own sales representatives. In addition, the company specialises in post-and-beam constructions for glass façades. The product range also includes entrance doors, whether manufactured in-house or as merchandise. Moser is also well positioned in interior design, especially in shop fitting and practice furnishings, by virtue of its cooperation with planners and property fitters.

Joiners and carpenters particularly appreciate the company's expertise in the Corian/mineral material sector. Moser employs 25 people in this department. With this team, he can respond flexibly to all market requirements. It mainly manufactures supplier parts for joineries, kitchen studios and the sanitary trade. He has been working with solid surface materials since 1986 and therefore knows all the strengths and weaknesses of the material from his own experience. Moser has also been represented in China since 2004. A joint venture was established with a Chinese window manufacturing company to produce wooden and wood-aluminium windows for the local market.

Combustion technology

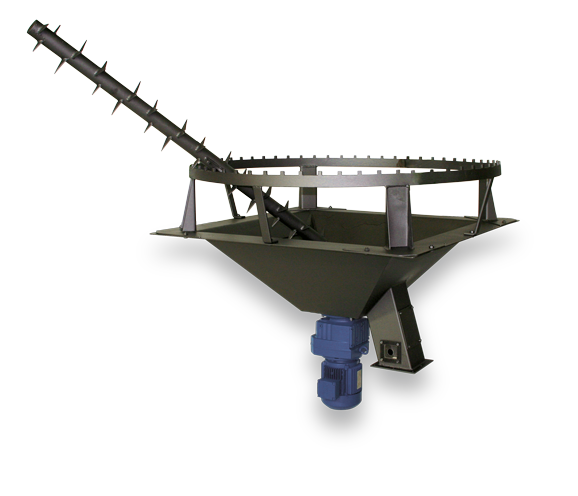

Underfeed combustion USF-W 800 | 600-800 kW

Filter technology

Tubular fabric filter RGF

Buffer tank

BUFFER TANK

Heating circuits

Heating circuit control

Fuel

Chips

In operation

since 2020

The challenge:flexible wood combustion for process heat and heating energy

The classic areas of window construction and interior finishing fill the Moser chip silo with significantly more fuel than could be used to generate heat in the wood combustion system. In addition, the company has made a name for itself with the processing of solid surface materials into high-quality moulded and composite parts such as washbasins, kitchen worktops and reception counters. For the production of 3D moulded parts, the plates have to be heated to more than 150 degrees °C, which is energy-intensive. Other problem areas that the new TGA concept was intended to solve: in summer, the workshop rooms were to be cooled in order to increase the time windows for painting the windows with water-based paint and for gluing the solid surface materials. The server room, offices and canteen should also be at a pleasant temperature. Another important criterion in the design of the system was that it should operate with as little noise and emissions as possible.

"The chimney sweep praises the exhaust gas values and the efficiencies. "*

Thomas Moser, Managing Director at Moser GmbH

The solution:Wood combustion system to produce cold for the heat and absorption refrigeration plant

A new wood combustion system from Endress with a firing capacity of 870 kW replaced the old plant with 550 kW. In order to enable consistent system operation, the heat is kept in a 24 m³ buffer storage tank and released to the heat consumers and the absorption refrigeration system according to demand. This in turn supplies the consumers in the production area and the pipe system for cooling the rooms via a cooling water circuit. A highly efficient bag fabric filter from ENDRESS ensures compliance with the emission limits of 0.02 g/m³ according to 1st BImschV. The new chimney was fitted with a flue gas silencer.

The new ENDRESS wood combustion system is powerful enough to cover the Moser joinery's entire demand for thermal energy, process heat, process cooling and room air conditioning. In addition, the system technology is extremely maintenance-friendly and low-wear. A maintenance contract also ensures permanent operational reliability. The Moser team can access the system control via the online service I-SPY and react immediately in the event of a malfunction.

*External source used: Report in dds ONLINE (https://www.dds-online.de/menschen/vor-ort-beim-kollegen/kaelte-aus-dem-heizkessel/)

Do you have any questions or would you like to receive individual advice from our professionals?

ENDRESS adapts your new combustion plant individually to your annual heat requirements, the type and quantity of waste wood produced and the space available on your site. Each offer is combined with a specific installation proposal.