Low-particulate, economical and future-proof

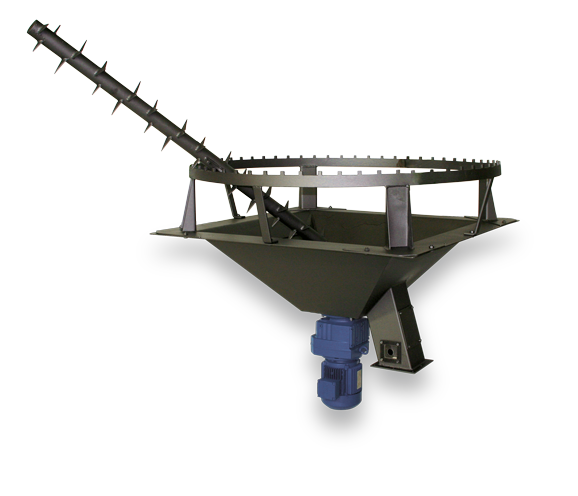

Originally for reasons of health protection, wood dust and chips are completely extracted and discharged into silos in companies in the timber industry and sawmill industry. Together with the shredded residual wood from the production process, tonnes of energetically valuable biomass accumulate, which can be used to generate heat for the hot water supply and the heating of the production halls, paint shops, drying chambers and social rooms. The waste is much too good to dispose of. On the contrary, most furniture factories sell off surplus fuel. Therefore, an efficient chip discharge system for rapid loading onto trucks constitutes an essential requirement for a wood combustion system.

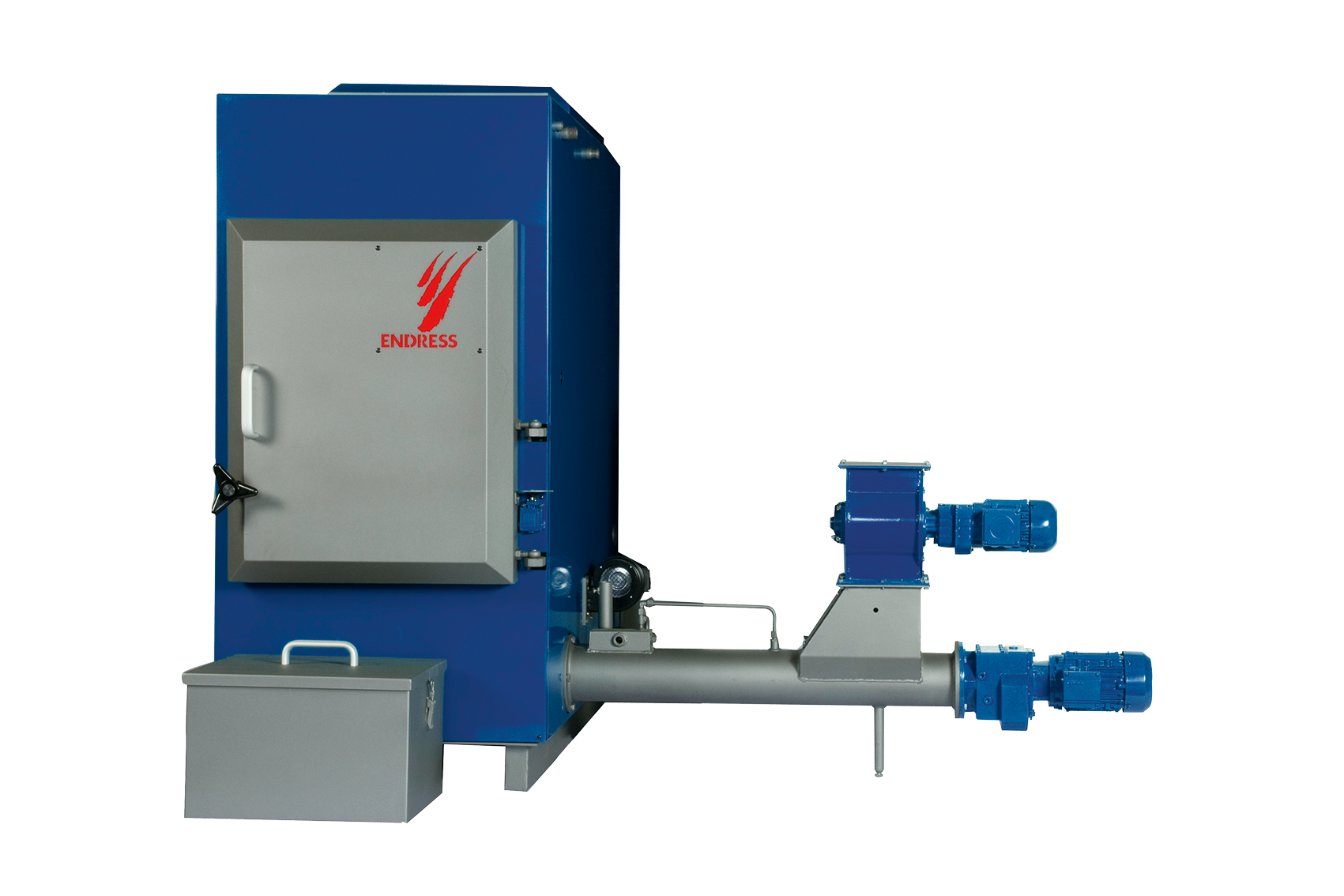

ENDRESS wood combustion systems with an output of up to 2000 kW as well as conveying technology and the matching buffer storage tanks are customised for fuel types, annual heat demand and space requirements.

Industrial scale wood heating and energetic wood utilisation

A 10-year guarantee on the boiler body testifies to the high industrial quality of ENDRESS combustion systems. In terms of energy efficiency, they do not have to shy away from comparison with fossil heating systems. On the contrary, the sophisticated design, in combination with the intelligent Lambdatronic control, achieves efficiencies of more than 90 %. The particulate matter filter specially developed by ENDRESS guarantees a separation efficiency of 99 % and keeps emissions permanently below the limit value of 0.02 g/m³ (according to the 1st Ordinance on the Implementation of the Federal Immission Control Act (BImschV)). ENDRESS wood combustion systems fit seamlessly within the processes of the wood industry by virtue of many comfort functions: Automatic ignition, automatic heat exchanger cleaning, automatic ash discharge, alarming and remote access to the control.

Do you have any questions or would you like to receive individual advice from our professionals?

ENDRESS adapts your new combustion plant individually to your annual heat requirements, the type and quantity of waste wood produced and the space available on your site. Each offer is combined with a specific installation proposal.